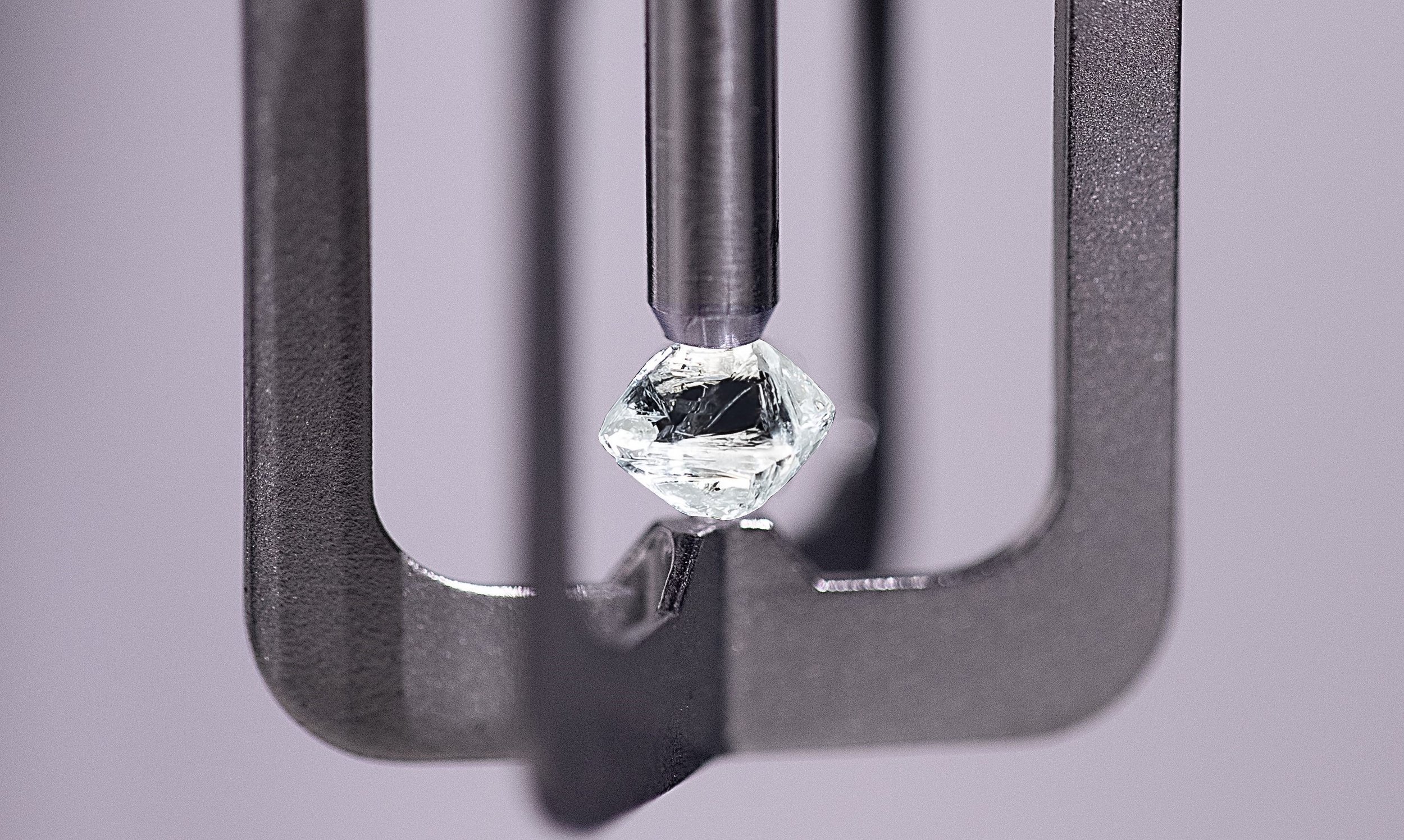

Rough To Polish

Planning

We use the worlds leading rough diamond planning system, Sarin, to optimally plan manufacturing instructions for rough diamonds.

Sawing

Our laser cutting machines allow us to easily undertake the cleaving process where the rough diamond is split into different pieces.

Bruting

After the diamond is split, we perform the bruting process to make the separated rough stones round. By the end of it, the rough diamond somewhat forms into a polished diamond.

Polishing

After bruting, our expert polishers form the facets of the diamond. This process is divided into 2 parts: blocking and brillianteering. This is the most crucial stage in creating “The M.Tarun Make”.